Some Known Incorrect Statements About Sheroz Earthworks

Not known Facts About Sheroz Earthworks

Table of ContentsWhat Does Sheroz Earthworks Do?Not known Details About Sheroz Earthworks All about Sheroz EarthworksThe smart Trick of Sheroz Earthworks That Nobody is DiscussingOur Sheroz Earthworks Diaries

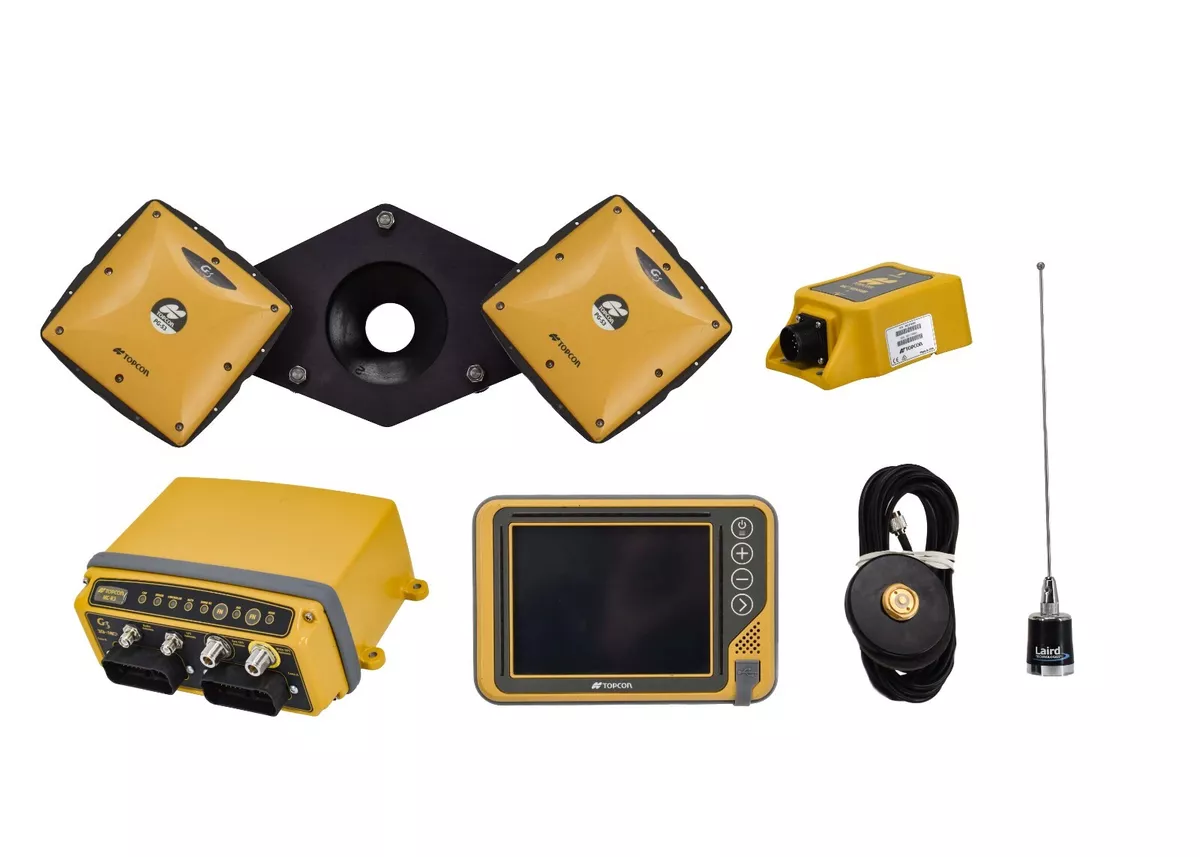

Machine: Makers are a sort of rover that service providers use to change the ground on a website, such as leveling. Vagabond GPS receiver: Vagabond GPS receivers are attached to the top of posts on rovers. They grab general practitioner signals to determine the vagabond's area, which they after that transmit to the data collector.

Equipment blade: Maker blades are the parts of an equipment that cut the ground into the wanted form. In maker control, they're often connected to rovers as a counterpart to the GPS signal, functioning with it for greater accuracy.

Machine control modern technology supplies the accurate measurements you call for to satisfy your high accuracy standards. https://anotepad.com/note/read/r7asbxrs. With this device, you'll experience consistent results from one job to the next, enabling you to satisfy your efficiency goals. These systems allow you to function faster and complete your jobs on time, which consequently allows you to take on more work and boost earnings

Rumored Buzz on Sheroz Earthworks

Maker control systems can help you decrease workplace crashes that maintain employee off the task, lead to costly workers' compensation, lower performance and perhaps cause Occupational Safety and Wellness Administration violations. This modern technology assists your staffs attain these vital purposes by boosting exposure and awareness, making it possible for employee to prepare for and prevent possibly hazardous situations prior to they occur.

Is your firm seeking to operate leaner and save money by saving valuable sources? Machine control assists you reduce worldly waste, which can considerably boost your business's lower line. Your building or having firm will certainly also come to be a better steward of the setting, which is essential for boosting public relations and enhancing customer acquisition and retention.

Advanced maker control technology options aid your devices run extra effectively and cost-effectively. This automation can additionally reduce rework, which is another advantage that permits you to stay clear of unexpected and expensive project hold-ups. Time is cash in the construction company the much faster your firm can complete its tasks, the more income it can produce using an increased workload.

Some Ideas on Sheroz Earthworks You Should Know

You might additionally experience decreased downtime by enhancing your devices and resources. With access to relevant, real-time information, you'll have the ability to make faster, a lot more educated service decisions that give your company an one-upmanship. You can likewise participate in proactive strategic preparation instead of reacting to what the remainder of the sector is doing.

You'll discover that a device control system helps you create quicker cycle times and enhanced output in numerous work processes and task kinds. You may additionally experience far better performance from your tools by maximizing usage. From an operational viewpoint, you're most likely seeking means to reduce labor costs, which can represent one of the largest expenses in a construction task.

One of the most forward-thinking building entities count on targeted, relevant data for the effective planning and execution of every job action. https://sherozau.edublogs.org/2024/05/08/sheroz-earthworks-mastering-precision-with-topcon-gps/. Some of the most important benefits of equipment control are precise and extensive data collection capacities, consisting of real-time tracking and coverage, right within your reaches. As an entrepreneur or manager, you'll be able to make quickly, precise data-driven decisions that boost accuracy and obtain a substantial market and competitive benefit

The 5-Minute Rule for Sheroz Earthworks

We've currently covered all the aspects of maker control systems, and just how they function. What is maker control used for in the actual construction procedure?

Here's how maker control can be related to numerous of them. Excavating: Excavation includes digging out slopes and trenches on building websites, whether to level a building surface area or to lay pipelines. Certainly, digging large chunks of dirt go now is much from a specific process, so maker control systems can be a significant asset to excavators.

Leading: Leading equipment is designed to spread out and squash concrete or asphalt. fj dynamics auto steering kit price. With functions like automatic guiding, device control can route paving lorries along their path at precisely the desired alignment and incline.

Sheroz Earthworks Things To Know Before You Get This

Stacking: Piling refers to the process of placing huge amounts of difficult materials like concrete, steel or timber right into the ground. These materials are meant to provide additional toughness to the structure of whatever framework is improved the site. Piling equipment can make use of machine control to make sure that it's inserting all products at the appropriate angle and in the ideal spot.